China's journey in the tungsten carbide sector began decades ago, leveraging the country's abundant tungsten resources. As the world's largest producer of tungsten, China naturally extended its capabilities into the production of tungsten carbide. This material is essential for a wide range of industrial applications, including cutting tools, mining equipment, and wear-resistant parts.

By the early 2000s, Chinese companies started to invest heavily in research and development, aiming to close the technology gap with established Western and Japanese manufacturers. These efforts have paid off, with Chinese firms now commanding a significant share of the global market for tungsten carbide products.

One of the most notable advancements by Chinese companies is in the production technology of tungsten carbide materials. Companies such as Zhuzhou Cemented Carbide Group Co., Ltd. (ZCC) and Xiamen Tungsten Co., Ltd. have developed sophisticated processes for producing high-quality tungsten carbide powders. These powders are characterized by their uniform particle size distribution and high purity, which are crucial for producing superior end products.

Chinese manufacturers have also excelled in the sintering process, a critical step in tungsten carbide production. Advanced sintering techniques, such as spark plasma sintering (SPS) and hot isostatic pressing (HIP), have been adopted to enhance the mechanical properties and performance of tungsten carbide components. These methods allow for the production of materials with higher density and fewer defects, resulting in improved durability and wear resistance.

In the realm of tungsten carbide molds, Chinese companies have made significant strides in both design and manufacturing. Tungsten carbide molds are essential for various industries, including automotive, electronics, and metalworking, due to their superior hardness and resistance to deformation under high stress.

Chinese firms have focused on innovation in mold design to enhance efficiency and extend the service life of the molds. Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies are widely used to create complex and precise mold geometries. Additionally, the integration of finite element analysis (FEA) allows for the optimization of mold designs to ensure optimal performance under operational conditions.

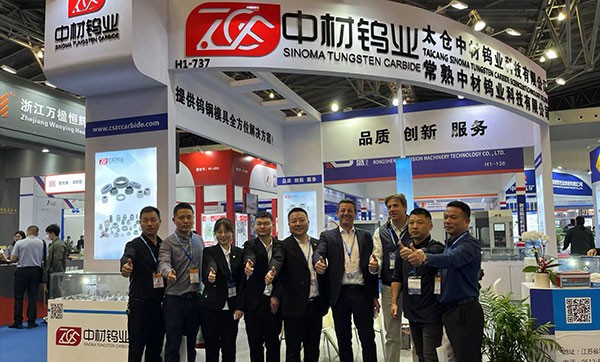

Manufacturers such as Changshu ZCCF and Taicang ZCCF have developed proprietary technologies for the fabrication of high-performance tungsten carbide molds. These companies utilize state-of-the-art machining techniques, including electrical discharge machining (EDM) and laser cutting, to achieve exceptional precision and surface finish.

To ensure the highest quality of tungsten carbide products, Chinese companies have implemented rigorous quality control measures throughout the production process. Adherence to international standards, such as ISO and ASTM, is strictly maintained. This commitment to quality has earned Chinese tungsten carbide products a reputation for reliability and performance in the global market.

Looking ahead, the future of Chinese tungsten carbide production appears promising. Continued investment in research and development is expected to yield further innovations in material properties and production techniques. The ongoing trend towards automation and smart manufacturing is likely to enhance production efficiency and consistency.

Moreover, the increasing demand for high-performance materials in emerging industries, such as renewable energy and advanced electronics, presents new opportunities for Chinese tungsten carbide producers. By maintaining their focus on quality and innovation, Chinese companies are well-positioned to meet these demands and further consolidate their leadership in the global market.

Chinese companies have made substantial progress in the production of tungsten carbide materials and molds, driven by technological advancements and a commitment to quality. From pioneering production techniques to innovative mold designs, Chinese firms have established themselves as key players in this critical industry. As they continue to innovate and expand their capabilities, the influence of Chinese tungsten carbide products is set to grow even further on the global stage.